The van arrived May 2021. I was expecting a lousy audio system and noisy experience while driving but the latter was worse than I expected.

First surprise was the audio system was better than expected and I decided that I would not upgrade the standard speakers until I heard them after soundproofing was done.

The plan was to do this in two stages.

Stage 1 – local audio shop line all surfaces (floor, doors, ceiling) in the drivers cabin and also remove the wipers and do the top of the firewall.

Stage 2 – the camper conversion would achieve a lot of sound dampening as follows:

The pop up roof is a fibre glass foam sandwich, exterior walls, side and back door are lined with sound proofing and the floor of the can will have a VW rubber mat, topped by 12 mm ply and then 3 mm vinyl.

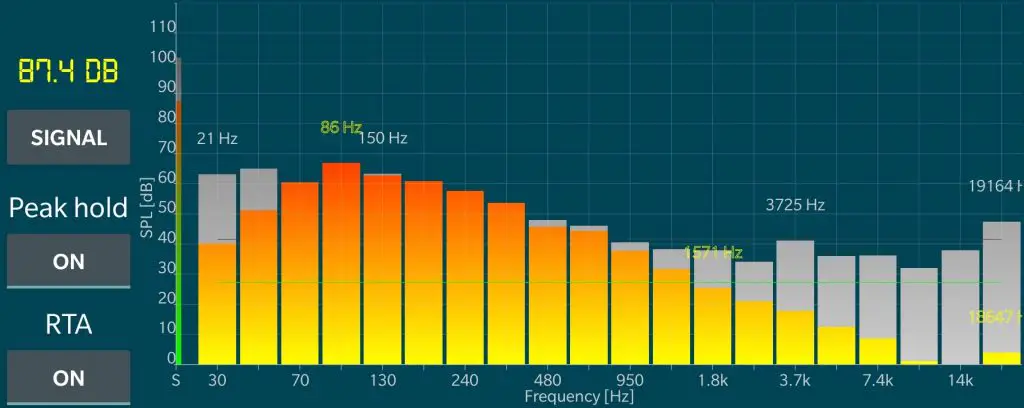

Am hoping for a significant improvement from our first journey on a highway with the following sound profile at 100 km/hour sitting in front of an empty steel box. Australian workplace health and safety regulations set the exposure standard for noise at 85 dB(A) so a VW Transporter should be considered a dangerous workplace.

Let’s hope we get a substantial reduction from the planned works.

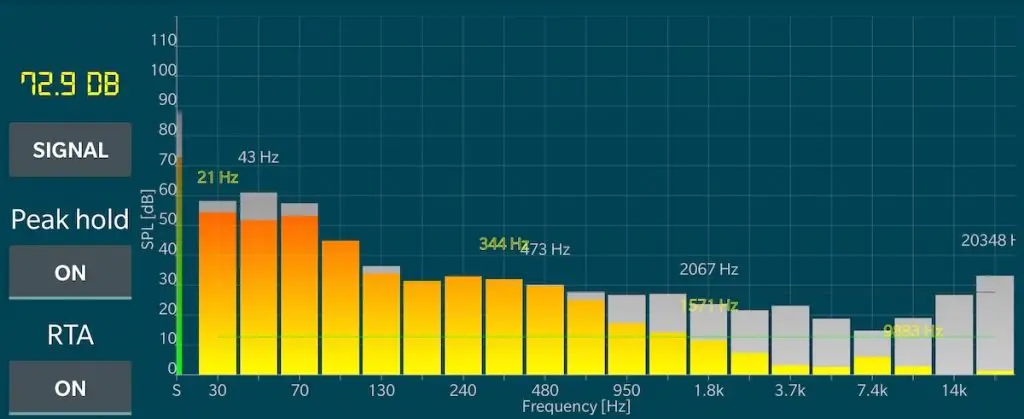

Here are the BEFORE specs.

IDLING in Park – BEFORE

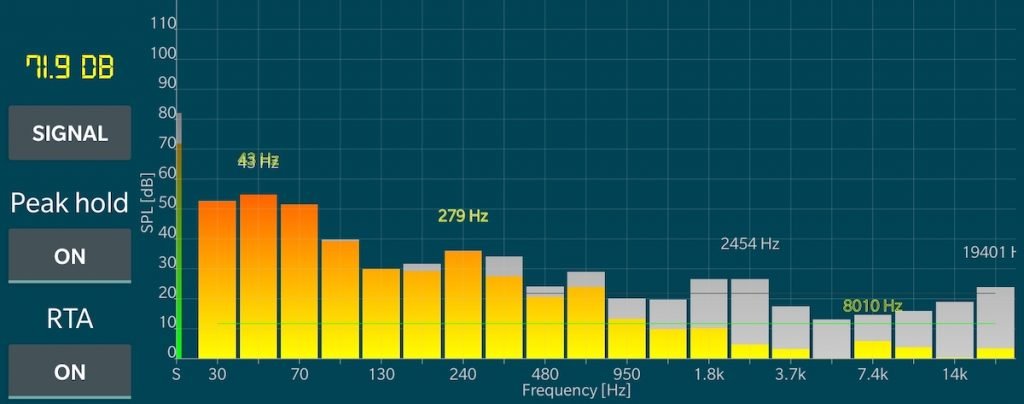

IDLING in Park – AFTER The sound profile below shows significant reductions at idle particularly in the lower frequencies. My observation of diving home was significantly less engine sound coming in and a dramatic improvement in the sound of the audio system. I will leave it till the camper is completed before making a decision to upgrade the audio hardware – I would prefer not to but….

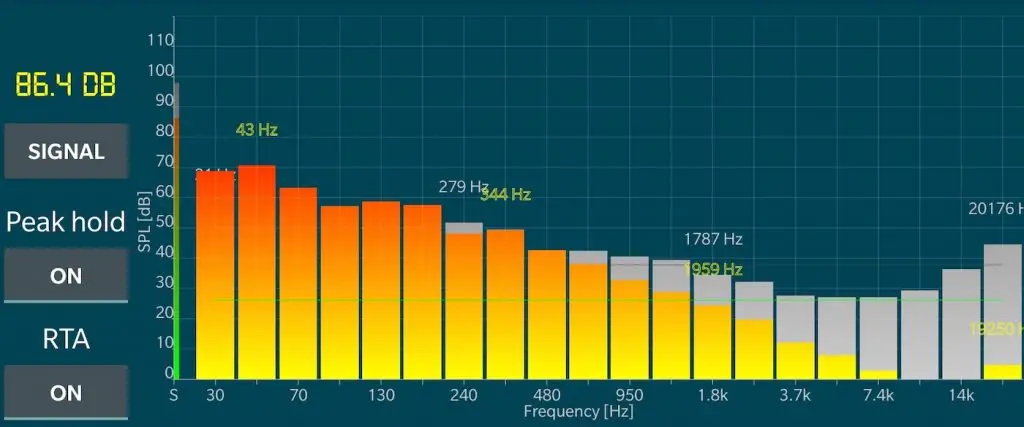

60 Km / Hr BEFORE

110 Km/Hr BEFORE

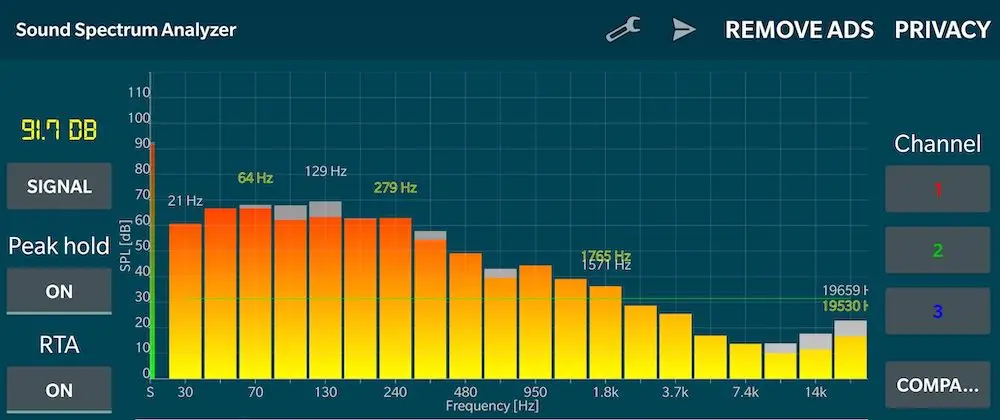

110 Km/Hr AFTER

Am not sure whether the Sound Spectrum Analyser app shows the before and after difference well.

To my ear the completed van is much quieter than the empty steel box. It is no where near as quiet as my wife’s SUV though but the sound system does not need to fight as hard to be heard now.

The sound proofing process was planned in two phases – see first phase focussed on the front cabin and engine bay.

See images of front door sound sound proofing

Leave A Comment